Precision You Can Trust, Results You Can Measure

Advanced industrial measurement solutions powered by Japanese technology ensuring precision, efficiency, and reliability in every application.

ABOUT YAKADO

Innovative Measurement Solutions For A Smarter Future

At Yakado, we specialize in advanced industrial measurement solutions powered by Japanese technology. With a commitment to precision, reliability, and innovation, we help industries optimize performance and ensure accuracy in every application. Our expertise in cutting-edge measurement technology enables businesses to achieve efficiency and excellence.

- Ensuring reliability and durability.

- Cutting-edge machinery and modern processes.

- A strong team of skilled engineers and experts

WHY CHOOSE US ?

We Prioritize Quality And Customer Satisfaction

Innovation & Excellence

Pioneering advanced metal fabrication techniques to enhance durability, efficiency, and precision in every product.

Cost-Optimized Solutions

Delivering high-quality metallic components with optimized manufacturing costs, ensuring affordability without compromising strength.

Sustainable Growth

Utilizing eco-friendly production methods and recyclable materials to drive long-term industry growth while reducing environmental impact.

Precision & Quality

Crafting high-performance metal products with stringent quality control, ensuring reliability and accuracy in every detail.

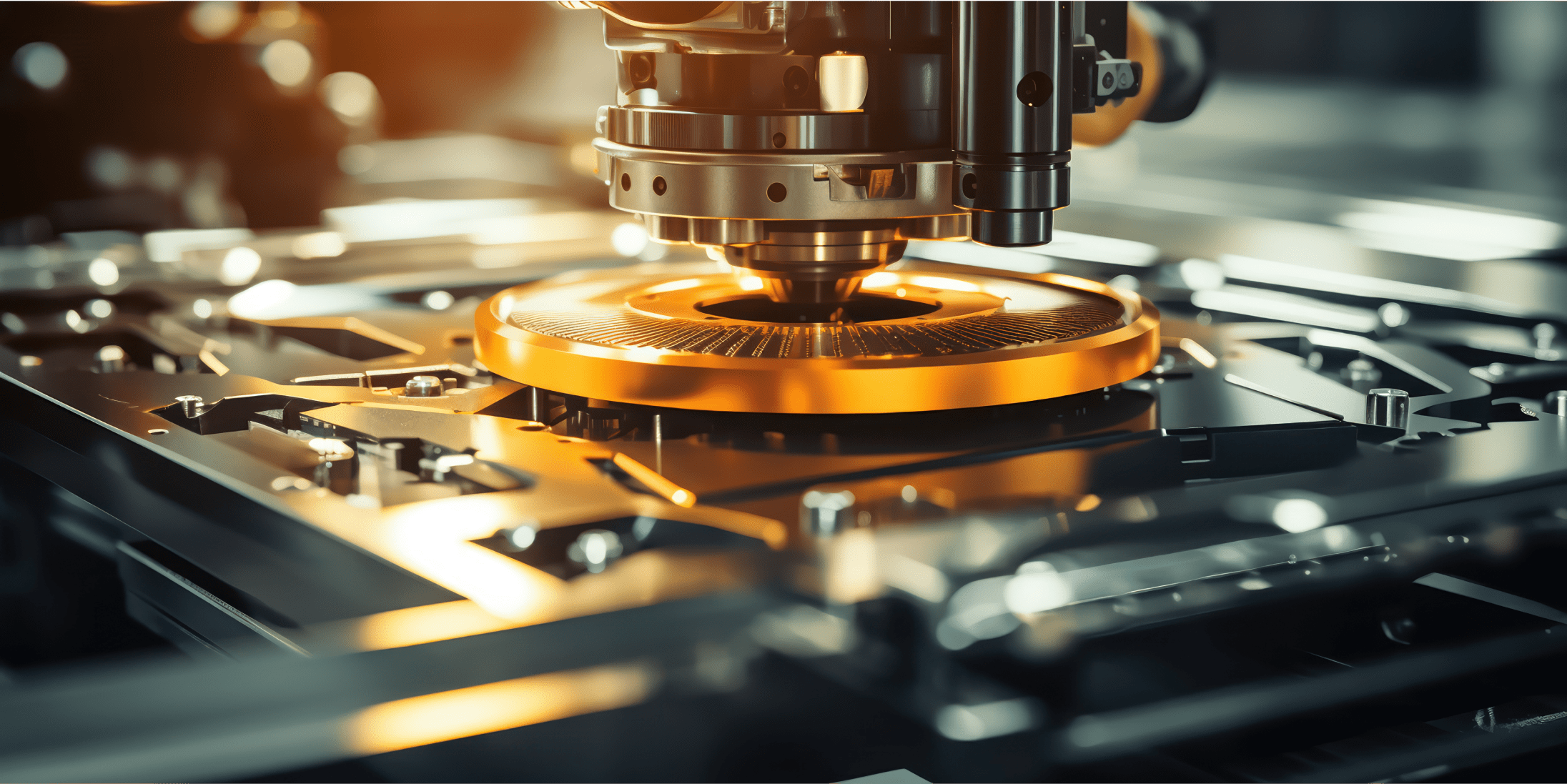

Advanced Automation

Incorporating state-of-the-art machinery and robotics to enhance production speed, consistency, and innovation in metallic manufacturing.

Reliable Customer Assistance

Providing dedicated support and tailored solutions to meet client needs, ensuring seamless integration and satisfaction.

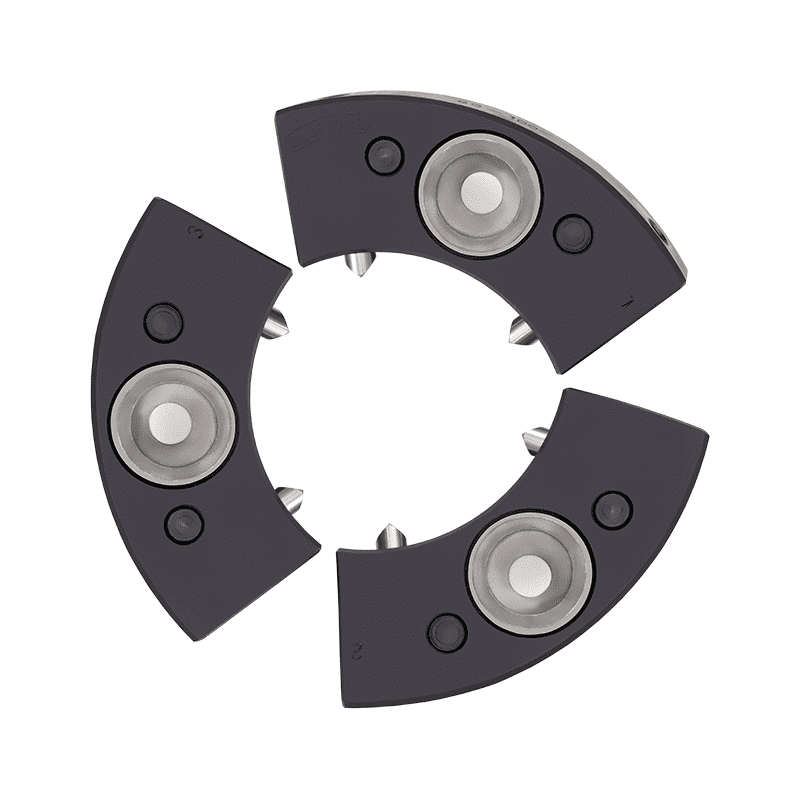

OUR PRODUCTS

High-Precision Instruments For Industrial Accuracy

Industries We Serve

Industries We Empower With Precision & Innovation

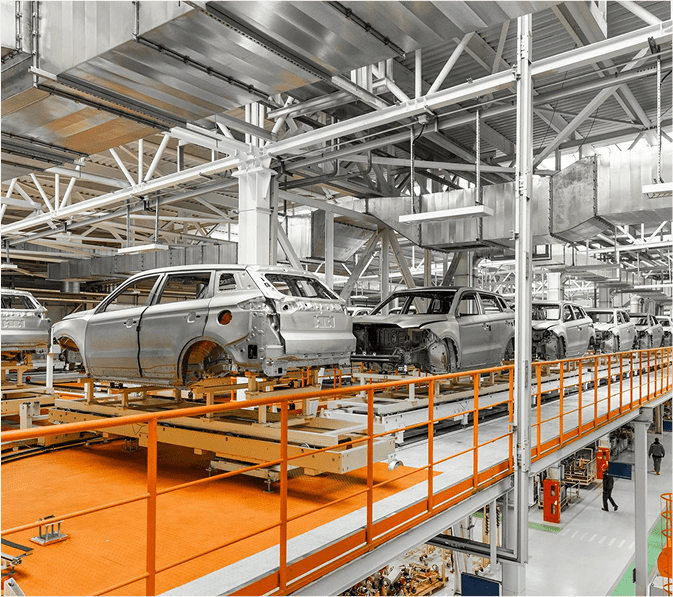

Automotive

The automotive industry requires high precision and durability in manufacturing vehicle components, from engine parts to body panels.

Manufacturing

Engineering solutions are continuously evolving to meet the demands of industries like aerospace, construction, and heavy machinery.

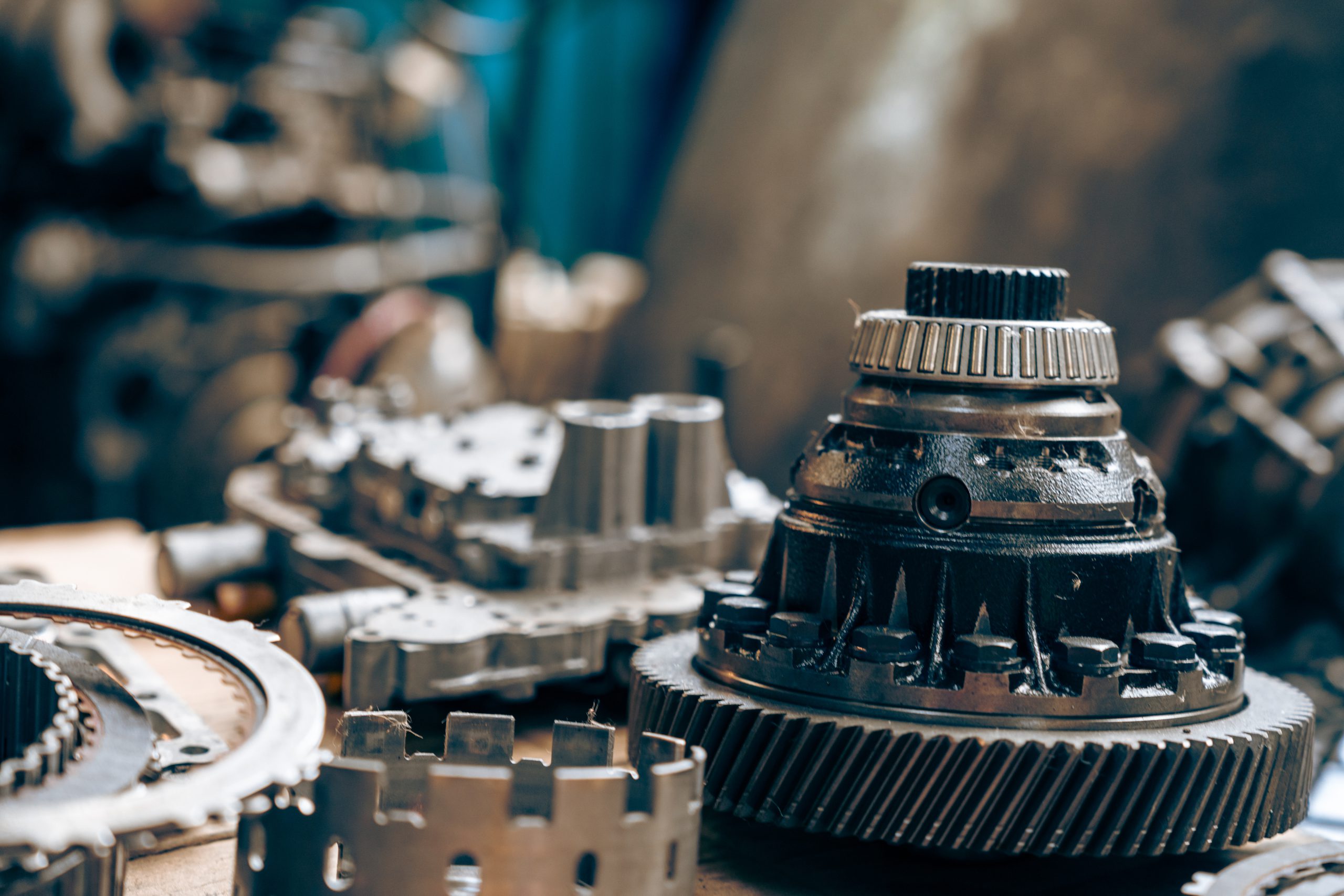

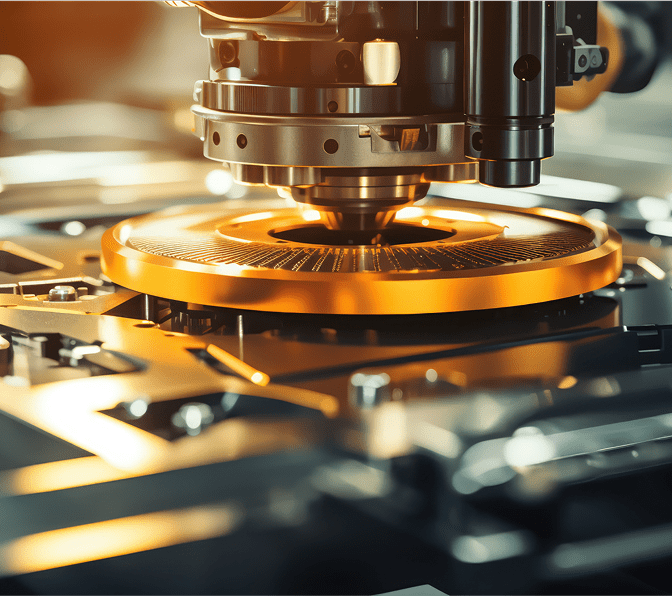

Metal Fabrication

The metal fabrication and sheet metal industry plays a vital role in producing components for construction, industrial machinery, electronics, and transportation.

Tool & Die Making Industry

Tool and die making is fundamental to mass production, shaping components used in manufacturing processes across multiple industries.

Construction & Heavy Machinery

Used for large-scale structural measurements and machine calibration.

Oil & Gas Industry

Ensures the accuracy of pipelines, drilling equipment, and safety systems.

Client Testimonials

Capturing Our Success Stories

Arvind Mehta

Neha Raghavan

Rajesh Patel

Faqs

Explore Our FAQs For More Information

What are precision measurement tools?

Precision measurement tools are instruments used to obtain accurate and consistent measurements in various fields like manufacturing, engineering, and scientific research. Examples include calipers, micrometers, dial indicators, height gauges, and CMMs (Coordinate Measuring Machines).

What industries use precision measurement tools?

Industries such as automotive, aerospace, electronics, medical device manufacturing, construction, and machining heavily rely on precision tools to ensure product quality and adherence to standards.

Do you offer calibration services for measurement tools?

Yes, we offer professional calibration services to ensure your tools maintain accuracy and comply with industry standards. Contact our support team to schedule a calibration.

How often should I calibrate my measurement tools?

Calibration frequency depends on usage, environment, and industry standards. Typically, tools should be calibrated every 6 to 12 months or after any significant impact.

Are your tools ISO certified?

Yes, our tools are manufactured to meet or exceed ISO standards for precision and quality. Specific certifications can be found on individual product pages.

YAKADO KNOWLEDGE HUB

Stay Ahead With Industry Trends & Innovations

Metal casting, a process that predates recorded history, continues to shape the world around us.

GET IN TOUCH

We’re Here To Help

Have questions or need expert guidance? Yakado is here to help! Reach out to us for precision solutions tailored to your industry needs. Let’s drive innovation together.

Address

Branch 1 : YAKADO ENGINEERS, East Vaidwadi - 5, Kismat Soda Street, Opp. D-Mart, Near Diesel House, Gondal Road, Rajkot - 360004

Branch 2 : YAKADO ENGINEERS, 29 - Samrath Industrial Area, Behind Jaynath Weigh Bridge, Near Sky Mall, Gondal Road, Rajkot - 360004

Phone No.

+91 94282 84652 (Mr. Jignesh Dodiya)

+91 94268 32130 (Mr. Nisarg Dodiya)

yakado@rediffmail.com